Comprehending the Causes and Solutions for Undercut Welding in Metal Fabrication Procedures

In the world of steel manufacture processes, the event of undercut welding poses a considerable challenge that requires a thorough understanding of its causes and sensible solutions. The detailed interaction of different aspects throughout welding operations can bring about this unfavorable sensation, impacting the structural honesty and overall quality of the welded joints - Preventing weld undercut. By dissecting the root creates of undercut welding and exploring efficient therapeutic measures, makers can raise the standard of their craftsmanship and make certain the manufacturing of remarkable steel components

Typical Reasons of Undercut Welding

Often neglected in steel fabrication, undercut welding takes place as a result of numerous aspects that demand meticulous interest and expertise to be successfully alleviated. One typical cause of undercut welding is excessive heat input. When the warmth input is also high, it can result in the melting and subsequent disintegration of the base material along the sides of the weld joint, developing a groove or undercut. Additionally, improper welding methods, such as making use of the wrong welding angle or travel rate, can additionally add to damage formation. Insufficient shielding gas protection is another vital aspect that can cause damaging. Insufficient gas coverage fails to shield the weld pool effectively, causing oxidation and undercut issues. Furthermore, the selection of welding parameters, such as voltage, current, and cord feed speed, plays a considerable function in the incident of undercut welding. Understanding these common reasons is essential for carrying out preventative actions and guaranteeing high-grade welds in steel construction processes.

Effect of Incorrect Welding Parameters

Imprecise welding parameters can dramatically endanger the honesty and high quality of welded joints in metal manufacture procedures. The influence of wrong welding specifications materializes in various ways, leading to architectural weaknesses and problems in the welded components. Thorough focus to welding criteria is extremely important to make sure the manufacturing of premium welds with the preferred mechanical residential or commercial properties and structural stability.

Result of Improper Torch Angle

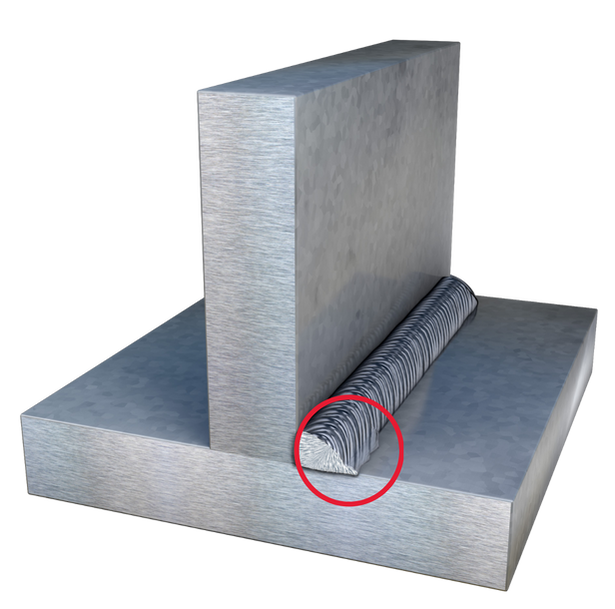

Inappropriate lantern angle in welding operations can significantly influence the quality and honesty of the last weld joints in metal fabrication processes. The lantern angle plays a critical duty in establishing the warm input and distribution throughout welding. When the torch angle is inaccurate, concerns such as undercutting can emerge. Damaging is a common welding issue where a groove creates along the weld toe, damaging the joint and jeopardizing its structural stability.

A lantern angle that is also high can result in inadequate infiltration, insufficient fusion, and raised spatter. On the other hand, a lantern angle that is also superficial can cause extreme penetration, burn-through, and distortion of the base material. Preventing blog here weld undercut. Correct torch angle is essential for ensuring constant weld top quality, strength, and look

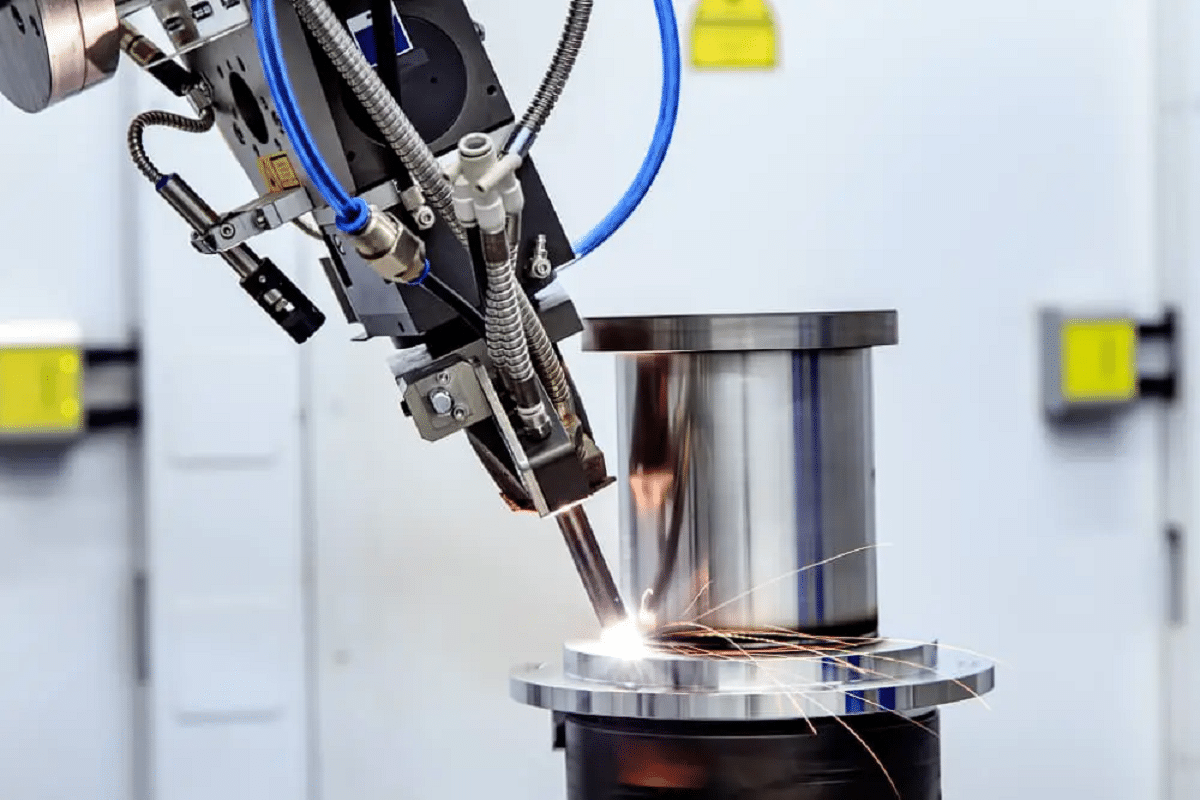

To prevent damaging and various other defects brought on by incorrect torch angles, welders have to be trained to maintain the correct torch angle throughout the welding process. Regular surveillance and modification of torch angles during welding can assist attain audio welds with very little issues.

Function of Inadequate Welding Strategies

Another element of poor welding techniques is improper weld preparation. Inadequate cleansing of the base steels, incorrect joint layout, or not enough side preparation can all add to undercut welding. In addition, poor shielding gas coverage or making use of the incorrect type of gas can result in insufficient combination and the development of undercut problems.

To deal with the role of insufficient welding methods in metal fabrication procedures, it is necessary to provide comprehensive training for welders. Proper education on welding specifications, joint preparation, and shielding gas option can aid protect against undercut welding and ensure high-quality welds in metal construction projects.

Effective Solutions for Undercut Welding

Attending to undercut welding in metal manufacture requires carrying out efficient solutions to boost weld high quality and structural stability. One of the primary remedies to combat undercut is to change welding specifications such as voltage, current, and take a trip rate to ensure correct heat input and fusion. By fine-tuning these settings, welders can protect against extreme melting of the base steel and filler material, lowering the probability of undercut formation.

Additionally, proper joint preparation is crucial in stopping undercut. Making sure clean base metal surfaces devoid of contaminants and utilizing the ideal bevel angle can help promote better weld infiltration and reduce the danger of undercut - Preventing weld undercut. Utilizing appropriate welding strategies, such check out here as weaving or oscillating the torch, can additionally help in dispersing heat equally and filling up the weld joint effectively, minimizing the opportunity of undercut issues

Moreover, picking the appropriate welding consumables, including electrodes and filler metals, is essential in reducing undercut. Making use of products with appropriate chemical compositions and mechanical homes can contribute to attaining sound welds with very little undercut. Routine evaluation and top quality control measures should additionally be executed to find and resolve undercut issues promptly, ensuring the overall stability of made steel parts.

Verdict

To conclude, understanding the causes and options for undercut welding in metal manufacture procedures is important for achieving high-grade welds. By attending to usual causes such as incorrect welding specifications, inappropriate lantern angle, and inadequate welding methods, welders can protect against damaging and make sure strong, resilient welds. It is vital to take notice of these aspects and execute effective services to improve the overall welding procedure and last item high quality.